YDTech® MANUFACTURER of precision CNC(go core machine) components; Supplier of CNC machine turning center parts in CHINA.

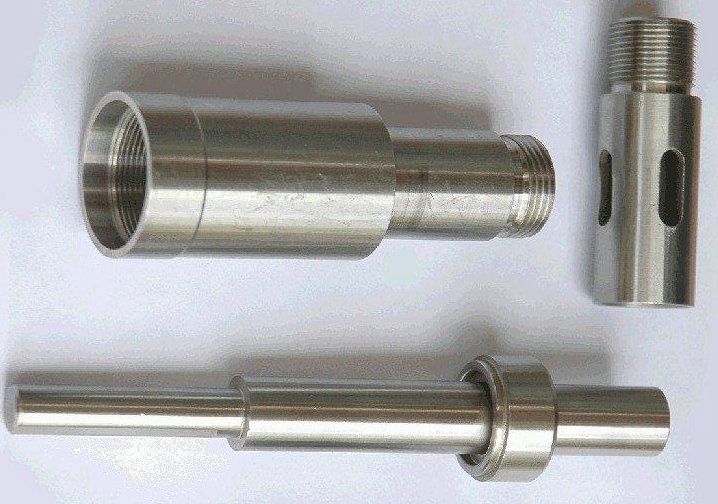

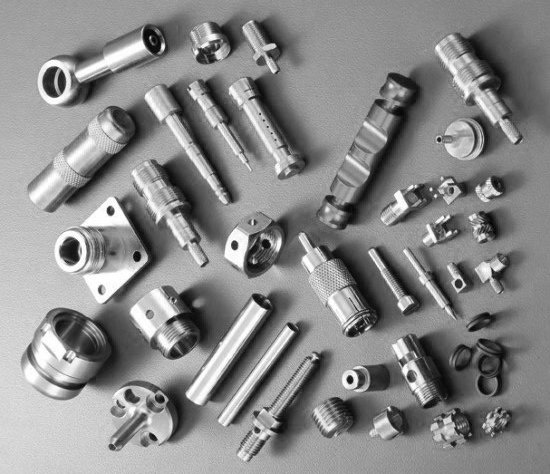

precision CNC machining parts

we are professional CNC machining manufacturer of aluminum CNCmachining parts,copper CNC machining parts and stainless steel CNC machining parts in China.

Application of CNC Parts

It is a multipurpose measuring instrument widely applied in machine building industry, electronics manufacturing industry and metrology testing. can measure various parts dimension, shape, angle and location with the range. the instrument processes measurement data with computer technology. meanwhile the measuring performance of instrument can be greatly enhanced by using image method, axis cutting method, contact method, two-beam interferometry and more measuring methods. Its composability and development greatly enhance the function of system, to widely meet the demands of users.

typical measuring objects:

all kinds of molded parts, such as template, template tools, template milling cutter, dies and cam;

pitch diameter, major diameter, minor diameter, thread pitch and half of thread angle for external thread like screw-thread, lead screw and worm, etc;

screw lead, tooth profile and thread angle of gear hob; hole location of circuit board/drilling jig, orifice, symmetry of key groove and other position errors.

within the numerical systems of CNC programming it is possible for the code generator to assume that the controlled mechanism is always perfectly accurate, or that accuracy tolerances are identical for all cutting or movement directions. This is not always a true condition of CNC tools. CNC tools with a large amount of mechanical backlash can still be highly accurate if the drive or cutting mechanism is only driven so as to apply cutting force from one direction, and all driving systems are pressed tight together in that one cutting direction. however a CNC device with high backlash and a dull cutting tool can lead to cutter chatter and possible workpiece gouging. Backlash also affects accuracy of some operations involving axis movement reversals during cutting, such as the milling of a circle, where axis motion is sinusoidal. however, this can be compensated for if the amount of backlash is precisely known by linear encoders or manual measurement.

- home

- products

- contact

- equipments

- drive pins

- needle rollers

- standard sizes or stocks

- needle roller bearings

- cylindrical rollers

- cylindrical roller bearings

- tapered rollers

- steel balls

- dowel pins

- CNC parts

- spherical rollers

- ceramic rollers

- Si3N4 rollers

- ZrO2 rollers

- miniature bearings

- valve balls

- tungsten pins